Foam Acoustic Panels: Reducing Noise in Industrial & Commercial Spaces

Noise pollution is a growing concern in today’s industrial and commercial environments. Whether it’s the constant hum of machinery, the echo of voices in open offices, or the clatter of weights in a gym, excessive noise can disrupt productivity, impact health, and create uncomfortable spaces for employees and customers alike.

“Loud noise causes hearing loss and tinnitus and can contribute to non-auditory health problems,” says the American Public Health Association (APHA) . “Chronic noise, even at low levels, can cause annoyance, sleep disruption, and stress that contribute to cardiovascular disease, cerebrovascular disease, metabolic disturbances, exacerbation of psychological disorders, and premature mortality.”

Fortunately, custom foam acoustic panels offer a proven solution to these challenges, providing effective sound management tailored to the unique needs of each space.

The Problem: Noise Pollution in Industrial & Commercial Spaces

Modern workplaces and facilities are often designed with efficiency and aesthetics in mind, but sound control is frequently overlooked.

In offices, open layouts and hard surfaces amplify conversations and background noise, making it difficult for employees to concentrate.

Machinery rooms are filled with equipment that generates high decibel levels, posing risks to hearing and overall well-being.

Gyms and fitness centers, with their hard floors and energetic activities, can become overwhelmingly loud, affecting both staff and patrons.

Unchecked noise pollution can lead to:

- Reduced productivity and focus

- Increased stress and fatigue

- Communication difficulties

- Potential hearing damage in high-noise areas

“Noise interferes with cognition and learning, contributes to behavior problems, and reduces achievement and productivity,” says the APHA. “Noise-related costs range in the hundreds of billions of dollars per year.”

Addressing these issues is essential for creating safe, comfortable, and efficient environments.

The Solution: Foam Acoustic Panels

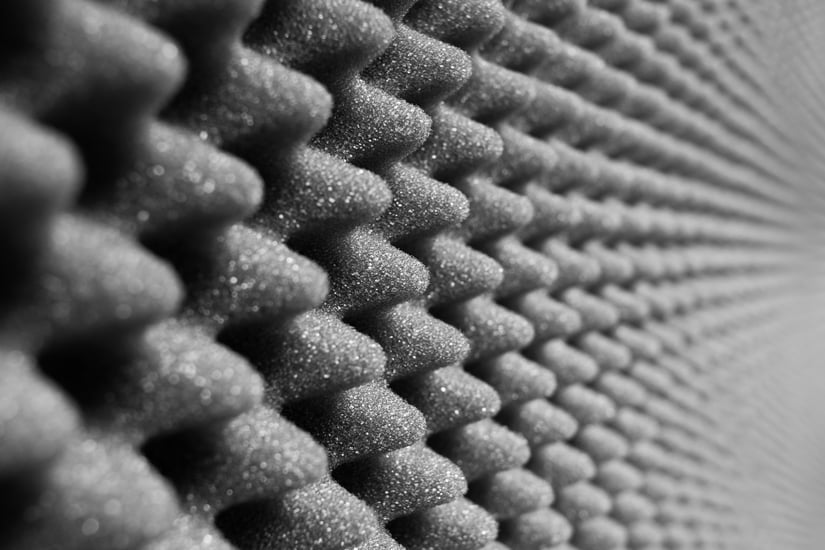

Foam acoustic panels are engineered to absorb and dampen sound waves, reducing reverberation and controlling noise levels within a space.

Unlike generic soundproofing materials, custom foam panels are designed to target specific frequencies and address the unique acoustic challenges of each environment.

This tailored approach ensures optimal sound management, whether the goal is to create a quiet office, a safer machinery room, or a more enjoyable gym experience.

“Acoustic wall panels are sound-absorbing panels that help absorb sound to minimize echo and background noise in your office. They use soft materials (e.g. soft acoustic foam) that help in better sound absorption,” explains Metro Office Fitouts. “Acoustic panels can also act as diffusers, which is great if they can’t absorb all of the sounds. The sound will bounce back into the room evenly. This can help keep the sound in the office from becoming too harsh.”

Key benefits of foam acoustic panels include:

- Superior sound absorption: Reduces echoes and background noise.

- Customizable design: Fits any space, from small offices to large industrial facilities.

- Easy installation: Panels can be mounted on walls, ceilings, or machinery enclosures.

- Durability: High-quality foam withstands daily wear and tear.

How Custom Foam Panels Work

Custom foam panels are crafted from specialized materials that trap and dissipate sound energy. When sound waves hit the foam, the open-cell structure allows air movement within the material, converting sound energy into heat and reducing the amount of noise that reflects back into the room.

The thickness, density, and shape of the foam can be adjusted to target specific frequencies, making custom panels far more effective than off-the-shelf solutions.

The Science Behind Acoustic Foam

- Absorption: Foam panels absorb mid- to high-frequency sounds, such as voices and machinery noise, preventing them from bouncing off hard surfaces.

- Diffusion: Custom shapes and patterns scatter sound waves, breaking up echoes and creating a more balanced acoustic environment.

- Isolation: In machinery rooms, foam enclosures can isolate noisy equipment, protecting workers and reducing noise transmission to adjacent areas.

By working with an experienced manufacturer, businesses can ensure their foam panels are engineered for maximum performance in their specific setting.

Applications: Offices, Machinery Rooms, Gyms, and More

Foam acoustic applications range from offices to manufacturing settings:

Offices

Open-plan offices are notorious for noise issues. Custom foam panels can be installed on walls, ceilings, and even as desk dividers to absorb conversations, phone calls, and other distractions. This creates a quieter workspace, improving concentration and employee satisfaction.

Machinery Rooms

Industrial environments often house equipment that generates significant noise. Custom foam enclosures and wall panels can dramatically reduce sound levels, protecting workers’ hearing and ensuring compliance with safety regulations. Panels can be designed to fit around specific machines, providing targeted noise control without hindering access or maintenance.

Gyms and Fitness Centers

Gyms are filled with hard surfaces and energetic activity, leading to high noise levels. Acoustic foam panels can be strategically placed to absorb the impact of dropped weights, music, and group classes, creating a more comfortable environment for both staff and members. Custom designs ensure the panels blend seamlessly with the facility’s aesthetic.

Additional Applications

- Conference rooms: Improve speech clarity and privacy.

- Retail spaces: Enhance customer experience by reducing background noise.

- Educational facilities: Create better learning environments by minimizing distractions.

Practical Benefits by Environment

|

Environment |

Foam Advantages |

|

Office & Meeting Rooms |

Quieter spaces boost productivity, reduce stress, and improve communication. Concentration gains have been reported when panels installed in classrooms, too. |

|

Machinery & Industrial Rooms |

Foam helps absorb and dampen machinery noise, making the workspace safer and more compliant with regulations. |

|

Gyms, Auditoriums, Studios |

Reduces reverberation, enhancing speech clarity, sound systems, and overall acoustic quality. |

|

Commercial Spaces |

Enhances privacy, client experience, and even contribute to energy savings through better insulation. |

Why Choose Sterling Manufacturing & Distributing?

For over 50 years, Sterling Manufacturing & Distributing has been a leader in custom foam solutions, serving clients worldwide with unmatched quality and expertise. Here’s why Sterling stands out:

- Experience: Thousands of successful projects across diverse industries.

- Customization: Every panel is designed to meet your specific acoustic needs.

- Quality: Rigorous standards ensure durable, high-performance products.

- Service: From design to delivery, Sterling’s team is committed to exceeding your expectations.

- Value: Competitive pricing and fast turnaround times mean you get the best solution without compromise.

When you choose Sterling, you’re partnering with the most trusted name in foam manufacturing — a company that takes pride in every order and continually refines its processes to deliver superior results.

Contact Sterling Manufacturing & Distributing today for a sample box and to discuss your project and discover how our expertise can help you reduce noise pollution, improve comfort, and create a better environment for everyone.

Leave a Comment

Your email address will not be published.